Ammonia Gas Leakage | 14 Apr 2025

For Prelims: Ammonia, Battery Electric Vehicles, Energy Density of Ammonia, Haber-Bosch process, Green Hydrogen/ Green Ammonia Policy, Occupational Safety, Health and Working Conditions Code, 2020, Labour Bureau, International Labour Organisation, ILO Conventions.

For Mains: Advantages and Challenges Related to Ammonia as a Fuel, Occupational safety and health in India - Analysis, Challenges and Steps that can be taken, Framework Regarding Labours in India, Grey Areas Related to the Current Labour Reforms

Why in News?

An ammonia gas leak at an ice factory in Ratlam, Madhya Pradesh, triggered panic among residents. Such chemical incidents highlight the recurring challenges of industrial safety and disaster preparedness in India.

Ammonia & its Industrial Applications

- Ammonia (NH₃) is a colorless gas with a sharp smell, widely used in industry and naturally found in the environment and human body.

- It is produced by the Haber-Bosch process (N₂ + 3H₂ → 2NH₃) under high temperature and pressure in the presence of a catalyst:

- Its concentrated form is corrosive and can cause burns or explode under high heat. It is stored as a compressed liquid.

- It is highly water-soluble and forms ammonium hydroxide in contact with water.

- It has 9 times the energy density of Li-ion batteries and 3 times that of compressed hydrogen, making it a promising carbon-free energy carrier.

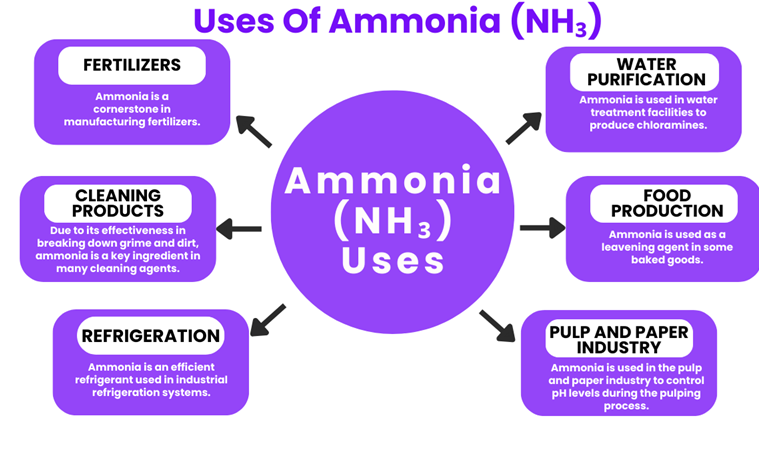

- Key Applications:

What are Industrial & Chemical Disasters?

- Industrial Disaster: An industrial disaster is a significant accident at an industrial site that results in extensive damage, injuries, or fatalities.

- It can result from various causes, including chemical, mechanical, civil, or electrical processes, as well as accidents, negligence, or incompetence.

- Types:

- Chemical disasters, Explosions, Mining disasters, Falling objects, Radiological incidents.

- According to the National Disaster Management Authority (NDMA), India reported 130 significant chemical accidents, resulting in 259 deaths and 563 major injuries over the last decade.

- Chemical Disaster: Chemical disasters are a type of industrial disaster involving the accidental release of hazardous chemicals, leading to mass casualties, long-term environmental damage, and socio-economic disruptions.

- They may result from industrial accidents, improper handling or storage of chemicals, or failure of safety systems.

- Notable Examples:

- Chennai Ammonia Leak (2024): Caused by a pipeline damaged during Cyclone Michaung.

- Vizag Gas Leak (2020): Styrene gas leak at LG Polymers, Visakhapatnam.

- Bhopal Gas Tragedy (1984): Methyl isocyanate leak from Union Carbide, causing mass casualty.

What are the Causes and Impact of Industrial Accidents?Click Here to Read: Causes of Industrial Accidents in India Click Here to Read: Consequences of Industrial and Chemical Accidents |

What are the Legal Safeguards against Chemical and Industrial Disasters in India?

- The Bhopal Gas Leak (Processing of Claims) Act, 1985

- The Environment Protection Act (EPA),1986

- National Environment Appellate Authority (NEAA) Act, 1997: Established the NEAA to hear appeals on environmental clearances ensuring transparency and accountability.

- Public Liability Insurance Act (PLIA), 1991: It mandates insurance for industries handling hazardous substances, ensuring immediate relief to victims of industrial accidents.

- Hazardous Waste (Management, Handling and Transboundary Movement) Rules, 1989: It imposes obligations on industries to identify accident-prone areas, undertake preventive measures, and report hazards to authorities.

- Additional Measures:

- NDMA Guidelines on Chemical Disasters: These provide a comprehensive roadmap for disaster risk reduction, mitigation, and preparedness specific to chemical hazards.

- Factories Act, 1948 contains safety provisions for workers in manufacturing units, including handling hazardous substances.

- Insecticides Act, 1968 regulates the import, manufacture, sale, and use of insecticides to prevent risk to humans and animals.

What are the Key International Conventions and Safeguards Related to Chemical and Disasters?

- Sendai Framework for Disaster Risk Reduction 2015-2030

- UN Convention on the Transboundary Effects of Industrial Accidents (1992) provides a legal framework for international cooperation in preventing, preparing for, and responding to industrial accidents that may have cross-border impacts.

- Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal (1989) regulates transboundary movement of hazardous wastes and ensures their environmentally sound disposal.

- Rotterdam Convention (2004) promotes shared responsibility in the international trade of hazardous chemicals and pesticides through the Prior Informed Consent (PIC) procedure.

- Strategic Approach to International Chemicals Management (SAICM), adopted in 2006, is a policy framework to promote chemical safety worldwide.

- UNEP’s Flexible Framework for Chemical Accident Prevention and Preparedness (CAPP), 2006 adopts a flexible approach to help countries, especially developing ones, build programs to prevent and prepare for chemical accidents.

- The OECD Programme on Chemical Safety and Biosafety (mid 1980s) deals with the safe use of chemicals, nanomaterials, pesticides, biocides, and products of modern biotechnology.

ILO Recommendations on Industrial Disaster PreventionClick Here to Read: What are ILO Recommendations on Industrial Disaster Prevention? |

What Measures can India Adopt to Reduce the Vulnerability of Chemical Disasters?

- Risk Mapping and Hazard Zonation:

- Conduct GIS-based hazard mapping of all Major Accident Hazard (MAH) units to identify vulnerable zones and mandate the creation of safety buffer zones, especially in densely populated industrial areas. This aligns with SDG 11 (Sustainable Cities and Communities) and SDG 3 (Good Health and Well-being), ensuring safer urban planning and reduced health risks.

- Institutional and Policy Reforms:

- Strengthen NDMA’s Chemical Disaster Management Guidelines through periodic review and alignment with global standards.

- Establish specialized institutions at national and state levels for training, planning, and integrating chemical disaster response into District and State Disaster Management Plans with clear SOPs and regular mock drills.

- Effective Enforcement:

- Enforce laws like the Factories Act, EP Act, The Manufacture, Storage and Import of Hazardous Chemicals (MSIHC) Rules, 1989 and Public Liability Insurance (PLI) Act with stringent penalties for violations.

- Ensure the presence of Emergency Response Centres (ERCs) integrated with police, fire, SDRF/NDRF, and health services, and mandate off-site emergency plans supervised by district authorities.

- Technological Surveillance:

- Deploy real-time monitoring, early warning systems, and surveillance mechanisms for chemical storage, handling, and transport.

- Simultaneously, promote industry-wide adoption of Hazard and Operability Studies (HAZOP) and Hazard Analysis (HAZAN) to ensure early identification and mitigation of potential risks.

- Incentives Support:

- To incentivise safety improvements, financial aid like tax breaks or subsidies can be offered for upgrading infrastructure and adopting new technologies.

Occupational Safety, Health and Working Conditions Code, 2020

- Safety Responsibilities: It outlines the duties of employers and employees to ensure workplace safety.

- Industry-Specific Standards: Mandates customized safety norms across various sectors.

- Focus on Worker Welfare: Ensures regulation of working hours, health conditions, leaves, and other welfare measures.

- Protection for Contract Workers: Recognizes and safeguards the rights of contractual and migrant workers.

- Gender Inclusivity: Enables women to be employed in all types of work across all establishments.

Conclusion

The chemical & industrial accidents in India underscores the urgent need for robust chemical disaster preparedness. As industrialization grows, India must prioritize institutional vigilance, community awareness, and technology-driven safety measures. A culture of "zero tolerance" for safety lapses is essential to protect lives, environment, and ensure sustainable development.

UPSC Civil Services Examination, Previous Year Question (PYQ)

Prelims:

Q1. In India, why are some nuclear reactors kept under “IAEA safeguards” while others are not? (2020)

(a) Some use uranium and others use thorium

(b) Some use imported uranium and others use domestic supplies

(c) Some are operated by foreign enterprises and others are operated by domestic enterprises

(d) Some are State-owned and others are privately owned

Ans: (b)

Mains:

Q1. With growing energy needs should India keep on expanding its nuclear energy programme? Discuss the facts and fears associated with nuclear energy. (2018)