Disaster Management

Industrial Accidents

- 30 May 2024

- 13 min read

For Prelims: Occupational Safety, Health and Working Conditions Code, 2020, Labour Bureau, International Labour Organisation, ILO Conventions.

For Mains: Occupational safety and health in India - Analysis, Challenges and Steps that can be taken, Framework Regarding Labours in India, Grey Areas Related to the Current Labour Reforms

Why in News?

Recently, an explosion in a chemical unit in Thane, Maharashtra, killed 11 people. Such industrial accidents in India and elsewhere in the world constitute a major problem for industrial establishments.

Industrial and Chemical Disaster

- Industrial Disaster: An industrial disaster is a significant accident at an industrial site that results in extensive damage, injuries, or fatalities.

- Such disasters can stem from various causes, including chemical, mechanical, civil, or electrical processes, as well as accidents, negligence, or incompetence.

- Types: Chemical disasters, Explosions, Mining disasters, Falling objects, Radiological incidents.

- Chemical Disaster: It is defined as the release or spill of a toxic chemical that results in an abrupt and serious disruption of the functioning of a society, causing widespread human, material, or environmental losses that exceed the ability of the affected society to cope using only its own resources.

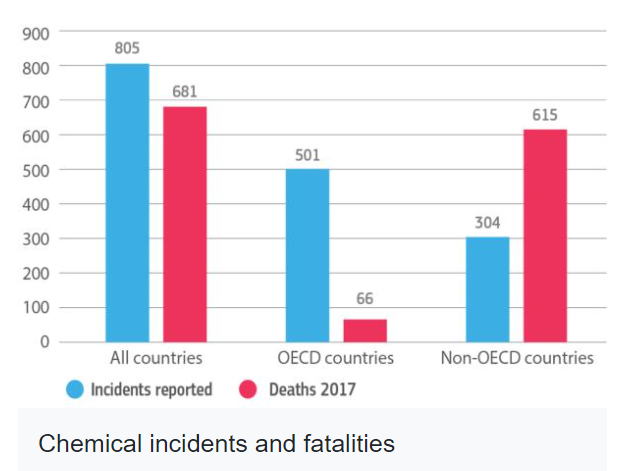

- According to the National Disaster Management Authority (NDMA), over 130 significant chemical accidents have been reported in the country in the last decade, claiming more than 250 lives.

What are the Key Factors Contributing to Industrial Accidents in India?

- Inadequate Regulation and Monitoring: Redundant regulations, including 15 Acts and 19 rules, lack a unified approach for the chemical industry. This fragmentation leads to overlapping jurisdictions and loopholes, weakening oversight and enforcement of safety measures.

- Lack of Comprehensive Chemical Risk Database: The lack of a central database on industrial chemicals and their risks creates a knowledge gap, hindering hazard assessment and safety protocol development.

- Insufficient Worker Training and Awareness: Boiler operation often falls to untrained, contractual workers, lacking proper safety and emergency response training as highlighted by IIT Kanpur.

- This leads to confusion during accidents and increases risks, especially with hazardous chemicals.

- Poor Investment in Worker Safety: Cost-cutting by some industries often neglects safety equipment and infrastructure, such as proper ventilation and fire safety.

- IIT Kanpur study (2023) stresses the need for increased investment in worker safety to reduce industrial accidents.

- Lack of maintenance: The Visakhapatnam gas leak involving benzimidazole raises concerns about maintenance and operations.

- In the Neyveli incident, a boiler being revived unexpectedly blew out, despite not being operational and mainly involving a furnace and steam production.

Major Industrial Disasters in India in the Past:

India has a long history of industrial accidents, with over 130 significant chemical mishaps reported recently.

- Bhopal Gas Tragedy (1984): The worst industrial disaster ever, a gas leak from a pesticide plant killed over 3,700 people and injured many more.

- Chasnala Mining Disaster (1975): An explosion in a coal mine caused by methane gas and a subsequent mine collapse led to the deaths of around 700 people.

- Jaipur Oil Depot Fire (2009): A fire at an oil storage facility resulted in 12 deaths and the evacuation of over half a million people. The lack of a proper disaster management plan was a major issue.

- Korba Chimney Collapse (2009): A chimney under construction collapsed due to poor construction practices, killing 45 workers.

- Mayapuri Radiological Incident (2010): Workers unknowingly dismantled a radioactive research irradiator in a scrapyard, exposing themselves and others to radiation.

- Bombay Docks Explosion (1944): A cargo ship carrying explosives exploded in Mumbai harbor, killing around 800 people and causing widespread damage.

What are the Consequences of Such Industrial and Chemical Accidents?

- Loss of Life and Injuries: Industrial accidents result in numerous fatalities and serious injuries. Example: The explosion at a chemical factory in Thane claimed 11 lives.

- Environmental Damage: Chemical leaks, explosions, and improper waste disposal can cause severe environmental damage (air, water, and soil pollution).

- Example: The Bhopal Gas Tragedy of 1984 serves as a horrific event, in which leak of methyl isocyanate gas from a Union Carbide plant resulted in thousands of deaths and long-term health problems for countless others.

- Economic Disruptions: The cost of repairing damage to facilities, compensating victims' families, and treating injured workers can be substantial.

- A study by the US Environmental Protection Agency (EPA) found that chemical accidents can decrease property values in surrounding areas by 5-7%, further impacting the local economy.

- Psychological Trauma: The trauma associated with industrial accidents can have long-lasting psychological effects on survivors, witnesses, and families of victims.

- Anxiety, depression, and post-traumatic stress disorder (PTSD) are common consequences.

- Loss of Public Trust: Frequent industrial accidents can erode public trust in regulatory bodies and industries. This can lead to public fear and resistance to new industrial projects.

ILO Recommendations on Industrial Disaster Prevention

- Identification of Hazardous Materials:

- Establish a list of hazardous chemicals and flammable gases based on their inherent risks and set specific threshold quantities.

- Any facility handling hazardous material exceeding the designated amount would be classified as a "major hazard workplace."

- Inventory of Major Hazard Workplaces:

- Each state should maintain a comprehensive inventory of major hazard workplaces within its jurisdiction with details like the type of facility, chemicals used, and quantities stored.

- Centralised Data Management:

- The list of hazardous materials and the inventory of major hazard workplaces should be stored in a centralised computerised database.

- This would allow for easier access to critical information by regulatory bodies, emergency responders, and the public.

What are the Legal Safeguards against Chemical/Industrial Disasters?

- International:

- Sendai Framework for Disaster Risk Reduction 2015-2030

- UN Convention on the Transboundary Effects of Industrial Accident (1992):

- It provides a legal framework for international cooperation on preventing and responding to industrial accidents.

- Parties share information, plan emergencies, and help each other during disasters. This reduces risk of widespread accidents.

- Flexible Framework for Accident Prevention and Preparedness (CAPP) (2006) of UNEP: It adopts a flexible approach to help countries, especially developing ones, build programs to prevent and prepare for chemical accidents.

- It also offers guidance on creating these programs considering a country's specific needs.

- OECD Programme on Chemical Accidents (1990): It focuses on preventing accidents through information sharing and best practices in chemical safety.

- India:

- The Bhopal Gas Leak (Processing of Claims) Act, 1985

- The Environment Protection Act, 1986 (EPA)

- The Public Liability Insurance Act, 1991 (PLIA):

- This act mandates insurance for industries handling hazardous substances.This insurance provides financial relief to those affected by accidents involving these substances.

- The National Environment Appellate Authority Act, 1997:

- This act establishes the National Environment Appellate Authority (NEAA), which hears appeals regarding restrictions placed on certain industrial activities under the Environment Protection Act, 1986 (EPA), ensuring a fair and transparent process.

- The Hazardous Waste (Management Handling and Transboundary Movement) Rules, 1989:

- It requires industries to identify significant accident risks, implement preventive measures, and report any potential hazards to the appropriate authorities.

- Additional Measures:

- The National Disaster Management Authority (NDMA) has issued specific guidelines on Chemical Disaster Management. These guidelines provide direction to various authorities for preparing detailed disaster management plans.

- Several other laws and regulations, like the Factories Act, 1948, and the Insecticides Act, 1968, also play a role in ensuring industrial safety.

Way Forward

- A Robust Regulatory Framework: ILO recommends a comprehensive national framework with clear roles for different government agencies to enforce safety regulations.

- World Bank (2018) suggested strong chemical safety regulations as key to reducing chemical accidents.

- Strengthened Monitoring and Enforcement: IIM Ahmedabad (2020), blames weak enforcement for India's industrial accidents. They recommend stricter penalties and more frequent inspections by qualified personnel.

- Building a Chemical Risk Database: The Bhopal Gas Tragedy of 1984 emphasises the critical need for a centralised database in India to document the risks associated with industrial chemicals.

- OECD promotes the Global Harmonized System of Classification and Labelling of Chemicals (GHS) offers a standardised way to classify these chemicals, aiding in better risk assessments.

- Investing in Worker Training: A 2017 National Safety Council of India (NSCI) study linked worker unawareness of safety protocols to a high number of industrial accidents.

- NSCI recommends comprehensive training programs with drills for all staff levels.

- Promoting Best Practices and Technologies: The UNEP encourages industries to adopt environmentally sound technologies (ESTs).

- ESTs can minimise the use of hazardous materials, improve waste management, and reduce the risk of accidents.

- Incentives and Support for Upgrading Safety Measures: To incentivise safety improvements, financial aid like tax breaks or subsidies can be offered for upgrading infrastructure and adopting new technologies.

The Occupational Safety, Health and Working Conditions Code, 2020

- Employer and Employee Duties: Defines responsibilities for both employers and employees regarding safety.

- Sector-Specific Safety Standards: Establishes safety standards for different industries.

- Employee Well-being: Focuses on worker health, working conditions, working hours, leaves, etc.

- Contractual Worker Rights: Recognises and protects the rights of contract workers.

- Gender Equality: Promotes gender equality by allowing women to be employed in all establishments for all types of work.

Conclusion

The tragic incidents of industrial accidents in India, underscore the urgent need to address the regulatory and knowledge gaps in the country's industrial landscape. By taking a holistic and proactive approach, involving both the government and industry stakeholders, India can work towards a safer and more sustainable industrial development.

|

Drishti Mains Question: Q. Frequent industrial accidents highlight serious regulatory deficiencies and inadequate safety measures. How can India bridge the knowledge gap and prevent future tragedies? |

UPSC Civil Services Examination, Previous Year Question (PYQ)

Prelims:

Q1. In India, why are some nuclear reactors kept under “IAEA safeguards” while others are not? (2020)

(a) Some use uranium and others use thorium

(b) Some use imported uranium and others use domestic supplies

(c) Some are operated by foreign enterprises and others are operated by domestic enterprises

(d) Some are State-owned and others are privately owned

Ans: (b)

Mains:

Q1. With growing energy needs should India keep on expanding its nuclear energy programme? Discuss the facts and fears associated with nuclear energy. (2018)