Governance

Using Green Hydrogen in the Steel Sector

- 17 Feb 2024

- 11 min read

For Prelims: National Green Hydrogen Mission, Steel Sector, Green Hydrogen, Decarbonization.

For Mains: National Green Hydrogen Mission, Government policies and interventions for development in various sectors and issues arising out of their design and implementation.

Why in News?

Recently, the Ministry of New and Renewable Energy has issued guidelines, named “Scheme Guidelines for Implementation of Pilot Projects for use of Green Hydrogen in the Steel Sector under the “National Green Hydrogen Mission”.

- It aims to replace fossil fuels and fossil fuel-based feedstock with Green Hydrogen and its derivatives.

- The Scheme will be implemented till FY 2029-30.

What are the Key Highlights of the Guidelines?

- Thrust Areas:

- Three areas have been identified as thrust areas for the pilot projects in the steel sector. These are:

- Use of Hydrogen in Direct Reduced Ironmaking process

- Use of Hydrogen in Blast Furnace

- Substitution of fossil fuels with Green Hydrogen in a gradual manner.

- The scheme will also support pilot projects involving any other innovative use of hydrogen for reducing carbon emissions in Iron and Steel Production.

- Three areas have been identified as thrust areas for the pilot projects in the steel sector. These are:

- Blending Approach:

- Steel plants are encouraged to begin by blending a small percentage of green hydrogen in their processes and gradually increase the blending proportion as cost economics improves and technology advances.

- Incorporation in New Plants:

- Upcoming steel plants are expected to be capable of operating with green hydrogen to participate in future global low-carbon steel markets.

- The scheme also supports greenfield projects aiming at 100% green steel.

What is Green Hydrogen?

- About:

- Hydrogen is a key industrial fuel that has a variety of applications including the production of ammonia (a key fertilizer), steel, refineries and electricity.

- Hydrogen is the most abundant element in the universe. But pure, or the elemental hydrogen, is very scarce. It almost always exists in compounds like with oxygen to form H2O or water.

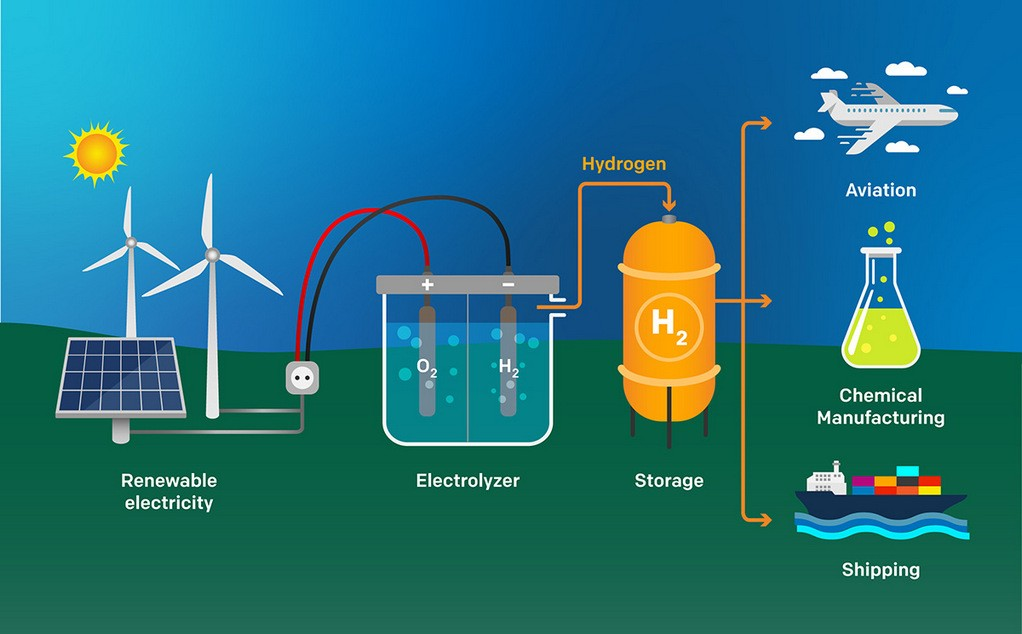

- But when electric current is passed through water, it splits it into elemental oxygen and hydrogen through electrolysis. And if the electricity used for this process comes from a renewable source like wind or solar then the hydrogen thus produced is referred to as green hydrogen.

- Colors attached to hydrogen indicate the source of electricity used to derive the hydrogen molecule. For instance, if coal is used, it is referred to as brown hydrogen.

- Need for Producing Green Hydrogen:

- Hydrogen is a great source of energy because of its high energy content per unit of weight, which is why it is used as rocket fuel.

- Green hydrogen, in particular, is one of the cleanest sources of energy, with close to zero emissions. It can be used in fuel cells for cars or in energy-guzzling industries like fertilizers and steel manufacturing.

- Countries across the world are working on building green hydrogen capacity, as it can ensure energy security and also help in cutting carbon emissions.

- Green hydrogen has become a global buzzword, especially as the world is facing its biggest-ever energy crisis and the threat of climate change is turning into a reality.

- Initiatives Related to Renewable Energy:

What are the Challenges in Adopting Green Hydrogen in Steel Plants?

- Technological Adaptation:

- Transitioning from traditional steelmaking processes to hydrogen-based methods requires significant technological adaptation. Existing steel plants may need to undergo substantial modifications or even complete redesign to accommodate hydrogen as a primary reducing agent.

- Infrastructure Requirements:

- The production, storage, and transportation of hydrogen necessitate significant infrastructure development. Establishing hydrogen production facilities, storage tanks, and distribution networks adds complexity and cost to steel plant operations.

- Cost Implications:

- Adopting hydrogen-based processes may incur higher initial capital costs compared to conventional methods. Investment in new equipment, infrastructure, and technology, as well as ongoing operational expenses, can pose financial challenges for steel producers, especially in the face of fluctuating market conditions.

- Supply Chain Constraints:

- Ensuring a reliable supply chain of hydrogen, including sourcing raw materials and maintaining consistent production levels, is crucial for uninterrupted steel plant operations. Dependence on external suppliers and potential supply chain disruptions may present logistical challenges.

- Carbon Capture and Storage (CCS):

- Although hydrogen-based steel production offers the potential for significant carbon emissions reductions, capturing and storing CO2 emissions generated during the process remains a challenge.

- Developing cost-effective CCS technologies compatible with steel plant operations is critical for achieving net-zero emissions targets.

What are the Efforts to Promote Green Steel Production?

- International Collaborations:

- At the 28th Conference of Parties to the United Nations Framework Convention on Climate Change, India announced its partnership with Sweden under the LEAD-IT initiative which had a focus on industrial Decarbonisation, specially the steel sector.

- Swedish company SSAB was the first globally to produce steel through hydrogen back in 2018.

- Yet another Swedish company, H2-Green Steel, is also planning to roll out its first batch of green steel using hydrogen by 2025.

- Similar initiatives are being taken by Nippon Steel in Japan and other competitors in France and Germany.

- At the 28th Conference of Parties to the United Nations Framework Convention on Climate Change, India announced its partnership with Sweden under the LEAD-IT initiative which had a focus on industrial Decarbonisation, specially the steel sector.

- Domestic Companies:

- Domestically, companies like Tata Steel and ArcelorMittal Nippon Steel India have started taking initiatives towards using hydrogen.

- In January 2024, ArcelorMittal Nippon Steel India signed a memorandum of understanding (MoU) with the Maharashtra government, proposing to establish a 6 million tonnes per annum green steel plant in Maharashtra that plans to use hydrogen instead of coal.

- Government Schemes:

- Perform, Achieve and Trade (PAT) Scheme:

- PAT Scheme incentivizes the steel industry to reduce energy consumption.

- Pradhan Mantri Urja Ganga Project to promote the manufacturing of Green steel.

- Steel Scrap Recycling Policy, 2019:

- Steel Scrap Recycling Policy, 2019 enhances the availability of domestically generated scrap to reduce the consumption of coal in steel making.

- Perform, Achieve and Trade (PAT) Scheme:

Way Forward

- Develop Supportive Policies and Regulations: India needs to develop a comprehensive and coherent policy framework for green hydrogen, such as setting targets, providing incentives, creating standards, and enforcing regulations. India can also learn from the best practices and experiences of other countries, such as Germany, France, and Sweden.

- Implement Pilot Projects and Scale-up: India needs to implement pilot projects using green hydrogen in steel plants, such as blending hydrogen with natural gas or coal, using hydrogen in the direct reduced ironmaking process, and using hydrogen in blast furnaces.

- These projects can help demonstrate the feasibility, viability, and benefits of green hydrogen, as well as identify the challenges and gaps.

- Based on the learnings and outcomes of these projects, India can scale up the adoption of green hydrogen in steel plants.

- Increase Investment and Collaboration: India needs to increase public and private investment in green hydrogen projects, as well as foster collaboration among various stakeholders, such as government, industry, academia, and civil society. India can also leverage international partnerships and initiatives, such as the International Solar Alliance and Mission Innovation.

- Enhance R&D and Innovation: India needs to enhance its R&D and innovation capabilities in the field of green hydrogen, such as establishing dedicated centers of excellence, supporting startups and entrepreneurs, and facilitating technology transfer and diffusion.

Supplementary Readings: Green Hydrogen: Enabling Measures Roadmap for Adoption in India, National Green Hydrogen Mission, Pitfalls of India's Green Hydrogen Move

UPSC Civil Services Examination Previous Year Question (PYQ)

Q. Hydrogen fuel cell vehicles produce one of the following as “exhaust” (2010)

(a) NH3

(b) CH4

(c) H2O

(d) H2O2

Ans: (c)

Exp:

- A fuel cell is a device that converts chemical energy (energy stored in molecular bonds) into electrical energy.

- It uses Hydrogen gas (H2) and Oxygen gas (O2) as fuel and the products of the reaction in the cell are water (H2O), electricity, and heat.

- This is a big improvement over internal combustion engines, coal-burning power plants, and nuclear power plants, all of which produce harmful byproducts. Therefore, option (c) is the correct answer.