India Plans USD 15 Billion for Chipmaking | 07 Sep 2024

For Prelims: Semiconductors, Microscopic switches, Ministry of Electronics and IT (MeitY)

For Mains: Significance and Challenges of India’s semiconductor Chip sector.

Why in News?

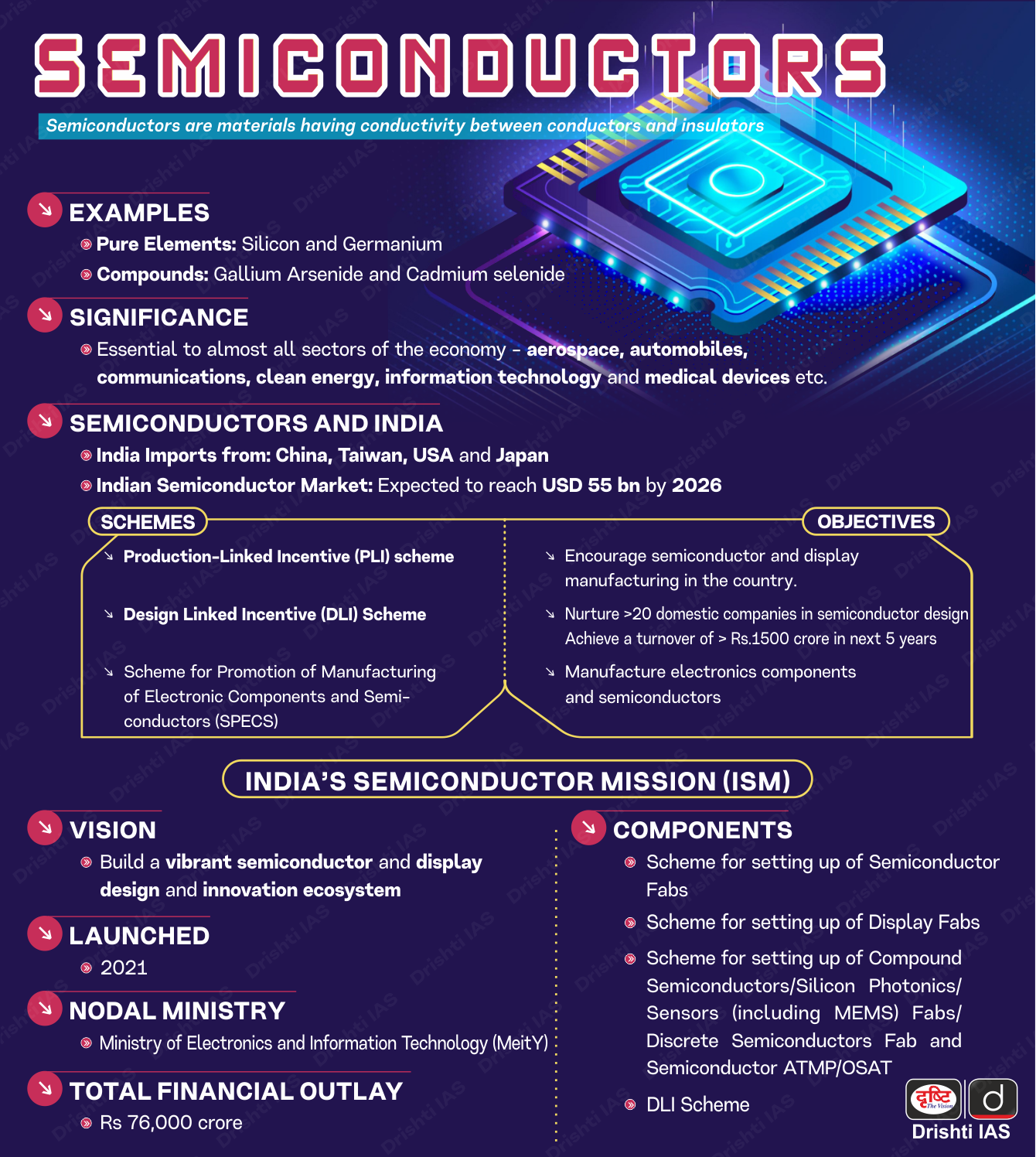

India is set to invest USD 15 billion for the second phase of chip manufacturing incentive policy (under India Semiconductor Mission). It had previously committed USD 10 billion for the first phase of the scheme.

- The government has also approved three assembly and testing plants, referred to as Assembly, Testing, Marking, and Packaging (ATMP) and Outsourced Semiconductor Assembly and Test (OSAT) in chip parlance, which are less complex than fabrication plants.

What are Semiconductor Chips?

- A Semiconductor Chip is a tiny electronic device made of semiconductor material (usually silicon or germanium) which serves as the basic building block of most electronic circuits.

- These chips can contain billions of microscopic switches on a chip smaller than a fingernail.

- The basic component of a semiconductor chip is a silicon wafer etched with tiny transistors that control the flow of electricity according to various computational instructions.

- It performs various functions, such as processing data, storing information, or controlling electronic devices.

- Fabrication Technology: It refers to the process of creating semiconductor devices like chips and transistors and involves several key steps, including wafer preparation, photolithography, etching, doping, and packaging.

What is the State of the Semiconductor Chips Industry?

- Globally, Taiwan and the US dominate the market of the Semiconductor Chips Industry.

- The US has implemented a semiconductor incentive scheme with an allocation of approximately USD 50 billion.

- Similarly, the European Union has also announced an incentive program of comparable scale to that of the US.

- India presently has an almost negligible presence in the semiconductor chip manufacturing sector.

- Need for Developing India’s Chipmaking Industry:

- Domestic fabrication plants are critical for bolstering India's economic and strategic interests, given that chips are used in practically all downstream industries from rockets to power steering in cars to kitchen toasters.

- The US and China are two of the most pivotal nations in the global technology value chain. Amidst escalating geopolitical tensions on the global stage, India seeks to capitalise on emerging opportunities to strengthen its domestic industry through government-funded initiatives.

- Need for Developing India’s Chipmaking Industry:

Recent Developments in India Regarding Chipmaking

- India recently signed a chip deal with Singapore, which has expertise in memory chips and logic processors. These are used in many electronic devices and automobiles.

- Tata is collaborating with Taiwan's Powerchip Semiconductor Manufacturing Corporation (PSMC) to build India's first commercial fabrication plant.

- Earlier in 2023, US-based Company – Micron Technology signed a Memorandum of Understanding (MoU) with the state government of Gujarat to establish a Semiconductor Unit worth Rs 22,500 crore near Ahmedabad.

- The project aims to contribute to India's Self-Reliance in memory chip manufacturing.

What are the Challenges of India Semiconductor Chipmaking Industry?

- High Capital Requirements: Semiconductor fabrication plants, or fabs, require substantial capital investments. The high cost of setting up and maintaining these facilities deters domestic players and limits the industry's expansion.

- Technology and Expertise Deficit: The semiconductor industry demands cutting-edge technology and a highly skilled workforce. India currently lags behind in advanced semiconductor research, design, and fabrication capabilities, leading to a dependence on foreign technology.

- Inadequate Infrastructure: The absence of robust infrastructure, including reliable power supply, water resources, and logistics, hampers the establishment and smooth functioning of semiconductor fabs. Additionally, the lack of specialised industrial zones for electronics manufacturing poses a significant hurdle.

- High Barrier Entry: The high barriers to entry in chip manufacturing are evident, as technology for producing cutting-edge chips is still underdeveloped in India, and competitors like Taiwan Semiconductor Manufacturing Company Ltd (TSMC) hold a significant advantage.

Way Forward

- Global Collaborations and Strategic Alliances: Bilateral and multilateral collaborations can help in technology transfer, joint ventures, and R&D partnerships.

- India's collaboration with the US and Taiwan are steps in the right direction that aligns with the government's goal of promoting domestic manufacturing and is expected to bolster India's position as a global semiconductor manufacturer.

- Similarly, India should leverage its diplomatic ties with South Korea to enhance its capabilities in the semiconductor chip manufacturing industry.

- Incentivizing Startups and SMEs: The government should create a favourable ecosystem for startups and SMEs in the semiconductor space by offering funding, incubation, and mentorship programs.

- Sustainability and Green Manufacturing: Emphasising sustainable practices in semiconductor manufacturing, such as reducing energy and water consumption, will be critical. Investing in green technologies and ensuring environmental regulations are aligned with industry growth will enhance the sector's long-term viability.

|

Drishti Mains Question: Q. Critically analyse the current state of India's semiconductor industry and discuss the strategic steps required to overcome these challenges and achieve self-reliance in semiconductor technology? |