Biodiversity & Environment

Converting Plastic Waste into Fuel

- 06 Jun 2023

- 8 min read

For Prelims: World Environment Day, Plastic, Plastic polymers, ICT-Poly Urja

For Mains: Environmental impact of plastic pollution, Solutions to Plastic-Waste Management, Recent Initiatives to combat Plastic waste

Why in News?

As the world observes the 50th anniversary of World Environment Day on June 5, this year's campaign, #BeatPlasticPollution, highlights the urgent need for global solutions to combat the pervasive issue of plastic pollution.

- The Department of Science and Technology (DST) is supporting a range of technologies aimed at addressing the global issue of plastic pollution. By focusing on reducing, reusing, and recycling plastic waste, they developed a Pilot scale mobile plant that converts plastic waste into fuel.

What is Plastic?

- About:

- The word plastic is derived from the Greek word plastikos, meaning “capable of being shaped or moulded.”

- It refers to a wide range of Synthetic or semi-synthetic materials derived from polymers, characterized by their plasticity and ability to undergo deformation.

- Modern plastics primarily originate from fossil fuel-based chemicals like natural gas or petroleum but can also be produced from renewable materials such as corn or cotton derivatives.

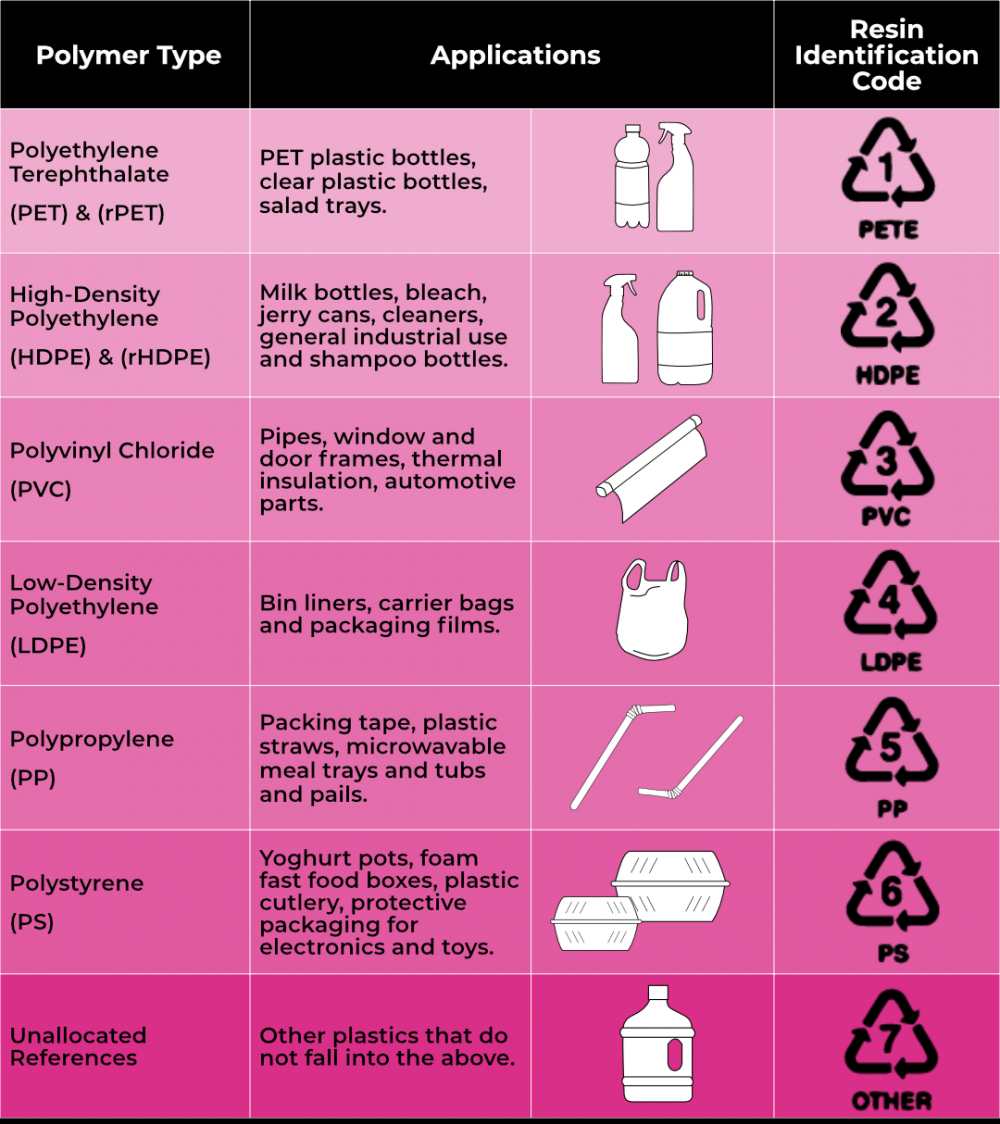

- Around 70% of global plastic production is concentrated in six major polymer types – referred to collectively as commodity plastics.

- These include

- Polyethylene terephthalate or PET,

- High-density polyethylene or HDPE,

- Polyvinyl chloride or PVC,

- Low-density polyethylene or LDPE,

- Polypropylene or PP,

- Polystyrene or PS,

- Other Plastics.

- Each of these has different properties and can be identified by their resin identification code (RIC) denoted by symbols found on plastic products.

- These include

- The word plastic is derived from the Greek word plastikos, meaning “capable of being shaped or moulded.”

What is Resin Identification Code?

- RIC was developed in 1988 by the Society of the Plastics Industry (SPI).

- Created to facilitate efficient sorting and recycling of plastics.

- Each RIC corresponds to a specific type of resin used in a plastic product.

- Proper recycling according to RIC preserves the value of the product.

- The American Society for Testing and Materials (ASTM) an international organization took over the administration of RIC after 20 years.

- RIC specifically applies to plastic, not glass, paper, or other recyclable materials.

- Microplastics:

- Microplastics are plastic particles measuring less than five millimeters in diameter.

- Primary microplastics are tiny particles designed for commercial use, such as in cosmetics or textiles, while secondary microplastics result from the breakdown of larger plastic items.

- Microplastics persist in the environment, contaminating the food chain, water sources, and air, and posing health risks due to toxic chemicals they contain.

- Decomposition Rate and Impact:

- Plastics have a slow decomposition rate, leading to their accumulation in natural ecosystems.

- Instead of breaking down into harmless substances, plastics fragment into smaller particles, contributing to the presence of microplastics.

- According to the most recent global estimates, an average human consumes at least 50,000 microplastic particles annually due to contamination of the food chain, potable water, and air.

- Microplastics contain toxic chemicals, with the biggest health risk being associated with BPA (Bisphenol A).

- BPA, used to harden plastic, contaminates food and drinks, leading to liver function alterations, insulin resistance, adverse effects on foetal development, reproductive system issues, and impacts on brain function.

- Note:

- The Great Pacific Garbage Patch (GPGP) also known as the trash vortex, located in the North Pacific Ocean between California and Japan, is the largest accumulation of plastic waste, formed by converging ocean currents.

How Plastic is Converted into Fuel?

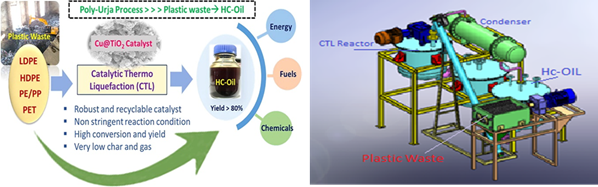

- Pilot Scale Mobile Plant:

- An indigenously designed process has led to the development of a vehicle-mounted mobile plant.

- The plant converts various types of plastic waste into carbon-densified HC-Oil (Hydrocarbon Oil) through a low-stringent process named ICT-Poly Urja.

- ICT Poly Urja is developed by the Institute of Chemical Technology (ICT) Mumbai.

- The presence of a selective, recyclable, reusable, and inexpensive catalyst enables low-cost conversion of plastic waste into fuel.

- ICT-Poly Urja Process:

- Different types of plastic waste, like bottles or packaging materials, are collected and sorted.

- A special substance called Cu@TiO2 catalyst is added to the plastic waste. This catalyst helps break down the plastic into smaller molecules.

- The mixture of plastic waste and catalyst is heated up under moderate conditions. This means it doesn't require extremely high temperatures.

- As the plastic waste is heated, it undergoes a chemical transformation called Catalytic Thermo Liquefaction (CTL). This process converts the plastic waste into a substance called Hydrocarbon Oil (HC-Oil).

- The resulting HC-Oil is a type of fuel that can be used for various purposes. It has a high energy content and can be burned to generate heat, steam, or even electricity.

- Efficient and Mobile:

- The CTL process requires less energy compared to traditional methods like pyrolysis and gasification.

- Moderate operating conditions contribute to energy efficiency.

- The mobile plant mounted on a vehicle offers operational benefits.

How is India Addressing the concerns regarding Plastic-Waste?

- National Dashboard on Elimination of Single Use Plastic and Plastic Waste Management.

- Plastic Waste Management Amendment Rules, 2022.

- India Plastics Pact.

- Project REPLAN.

UPSC Civil Services Exam, Previous Year Questions (PYQ)

Q. Why is there a great concern about the ‘microbeads’ that are released into environment? (2019)

(a) They are considered harmful to marine ecosystems.

(b) They are considered to cause skin cancer in children.

(c) They are small enough to be absorbed by crop plants in irrigated fields.

(d) They are often found to be used as food adulterants.

Ans: (a)

Exp:

- Microbeads are small, solid, manufactured plastic particles that are less than 5mm and do not degrade or dissolve in water.

- Mainly made of polyethylene, microbeads can also be prepared from petrochemical plastics such as polystyrene and polypropylene. They may be added to a range of products, including rinse-off cosmetics, personal care and cleaning products.

- Microbeads, because of their small size pass unfiltered through the sewage treatment system and reach the water bodies. The untreated microbeads in the water bodies are taken up by the marine animals, thus producing toxicity and causing harm to the marine ecosystem.

- In 2014, Netherland became the first country to ban cosmetics microbeads.

- Therefore, option (a) is the correct answer.